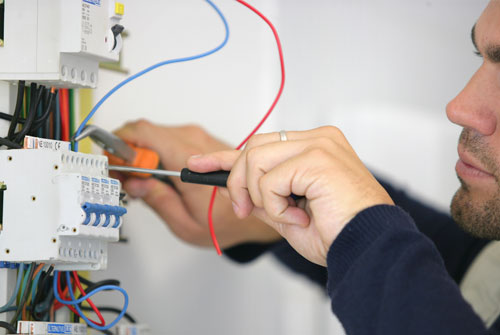

Industrial and Commercial Switchgear Safety

Professional installation of switchgear in London

When switchgear is installed, it needs regular checking and maintenance to ensure that it remains safe and working properly. We have encountered many situations where switchgear has been fitted in an industrial unit years ago and hardly looked at since. Changes to the network that feeds it such as an increase in the infeed capacity or changes to the systems fed from the switchgear can all contribute to over-stressing. Switchgear is over-stressed when the potential fault energy could exceed the fault rating.

Dangers of over-stressed switchgear

The worst case scenario is catastrophic failure which can occur when the switchgear is being operated under fault conditions. The equipment is unable to cope with the electrical and thermal stresses and something has to give. When it does, it gives in a big way – arc discharge products, hot oil mist if it is oil switchgear and even extremely high temperature gas clouds. Anyone in the vicinity of the failure would suffer serious burns or even death.

Manufacturers also issue safety bulletins that detail any upgrades that should be made to improve safety. The problem is getting these out to the end user. If you subcontract the installation and maintenance to South London Electricians, we keep abreast of developments and will automatically advise you of any switchgear upgrade work required.

You and your workforce benefit from improved health and safety.

Switchgear maintenance management

We are experienced commercial electricians with a wealth of experience of switchgear installation and management. Some aspects of your maintenance management will need to be done in-house:

policies for installation right through to removal and disposal

systems of records

identifying training

delegating responsibilities of your staff

effectiveness audit

Some of the decisions will require the input of consultants such as ourselves. We can advise on aspects like the frequency of inspection required based on the make, type, usage and age of your switchgear.

The maintenance is also best left to specialists such as South London Electricians, we can carry out inspections and any remedial work such as replacement of contacts plus routine servicing and testing such as lubrication, testing of the earthing equipment, verification of contact engagement or checking for deterioration due to corrosion. In-house maintenance teams will not always be up to date with standards and upgrades required.

New premises, old switchgear?

Prior to installing your three-phase or single-phase equipment on old switchgear, a good commercial electrical contractor will take into account a number of initial considerations to establish whether the switchgear should be replaced. For example, if it is a DMO (dependent manual operation) type and there is no chance of fitting new mechanisms, the switchgear should be scrapped. If it is fine to use it for your purpose, you are still not home and dry as you then need to assess the condition by visual inspection, testing, checking the documented history and availability of spares before installing any machines. At that point, the electrician can make the recommendation to replace, refurbish or use the existing system.

If you require commercial electricians in London to upgrade the single or three phase switchgear or wiring of your industrial unit, contact South London Electricians on 07956 523316 to find out how you can benefit from our expertise and experience.